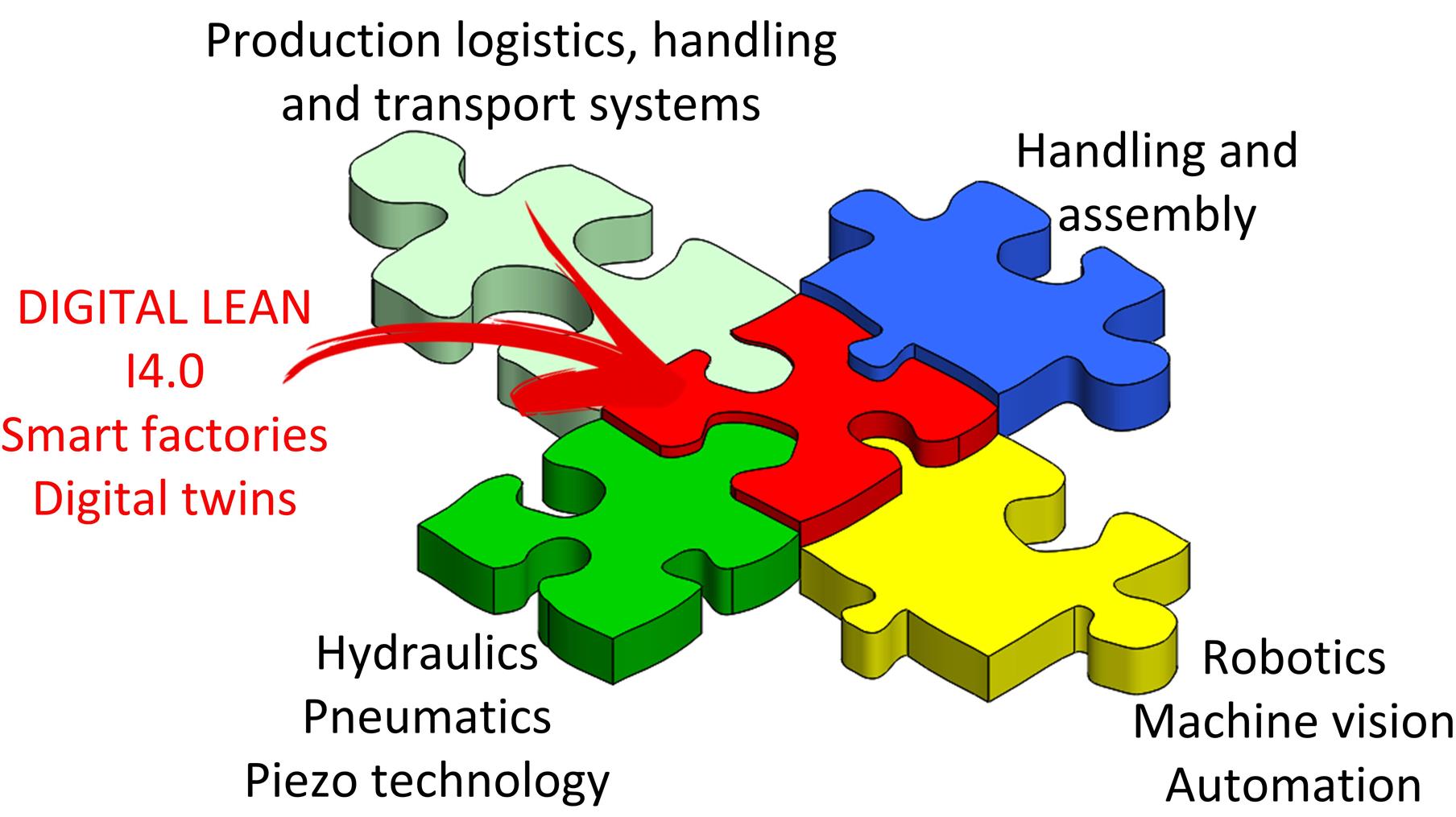

The laboratory for handling, assembly and pneumatics (LASIM) covers many research and development fields. In the last two decades, the research is focused on the development of advanced innovative processes and systems of manufacturing technologies, covering key enabling technologies of I4.0.

For the last 20 years our main area of research and development activities are modelling, simulation and optimization of real production processes. The most important aspects are the DIGITAL LEAN technology and the digitalization of real processes and systems, which are an integral part of all of the areas of our research. Within I4.0, we are mainly focused on: development of digital twins, development of intelligent decision algorithms (digital agents) and data management algorithms based on AI technology, modelling, simulation, optimization and monitoring of production processes, development of new innovative strategies on how to implement new technologies into the existing production processes, development of new architecture models and guidelines for the implementation of Smart factory concepts into the real world, integration of distributed systems, Internet of things and cloud computing technology, integration of additive technologies, VR and AR technology, RFID technology, smart robotics and smart tools, development of smart manual assembly stations and innovative assembly strategies.

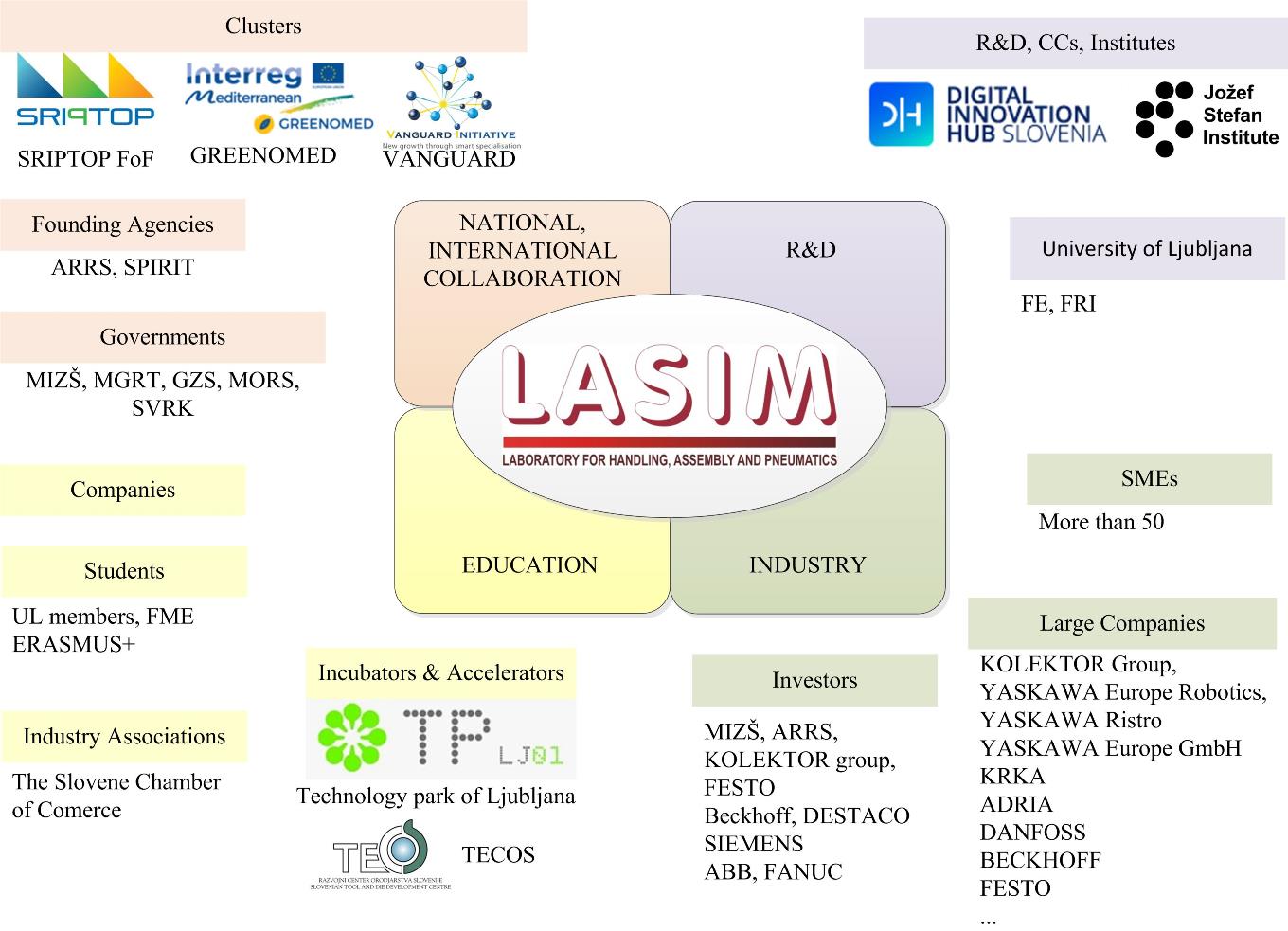

In our research, we cooperate with the most important institutions in Slovenia and the most innovative and successful companies. In addition to cooperation at the national level, we also cooperate with other international partners in the framework of European projects and initiatives.