Hybrid superhydrophobic surfaces for enhanced boiling heat transfer

5. May, 2020 10:45 | admin | News

Matic Može, Matevž Zupančič & Iztok Golobič from LTT and Matej Senegačnik & Peter Gregorčič from LASTEH were the first in the world to develop structured superhydrophobic surfaces exhibiting increased critical heat flux values in nucleate boiling of water. The results of their research are published in the ACS Applied Materials & Interfaces journal (IF = 8.456).

Reliable operation of advanced electronic systems depends on efficient dissipation of generated heat. Currently established thermal management approaches are mostly based on forced convection and extended surfaces. As they cannot keep up with the increasing heat flux, which is a consequence of rapid development of electronics and technology, new cooling methods exploiting latent heat during phase change (i.e., boiling and evaporation) are gaining prominence lately. Heat transfer enhancement in this field is mostly based on boiling surface functionalization, which affects the enhancement of its interaction with the cooling medium.

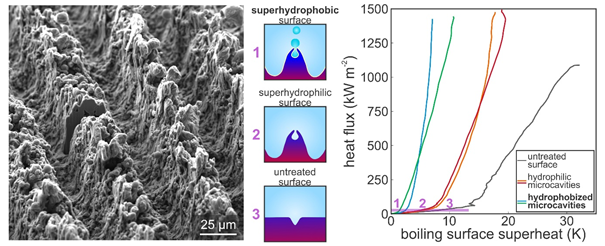

Modification of surface topography and wettability is a long-established approach to boiling heat transfer enhancement. However, superhydrophobic surfaces were not regarded as suitable for this purpose until recently, since they tend to cause a rapid transition towards the unwanted film boiling regime when water is used as the cooling medium and consequently do not allow for high heat transfer coefficients. In the recently published paper, the authors showed for the first time that fabrication of surfaces simultaneously exhibiting superhydrophobicity and increased critical heat flux values is possible. Heat transfer coefficients in excess of 200 kW m-2 K-1 were recorded on the developed surfaces at a surface temperature just 7.1 K above the temperature of the cooling medium (water). If the developed surfaces were used to cool a computer CPU, surface temperature just 2.3 K above the temperature of the cooling medium would be achieved at heat flux values typical for modern CPUs.

Superhydrophobic surfaces (with contact angle above 150° and roll-off angle below 5°) were fabricated on aluminum samples. The surface of the samples was laser textured to form microcavities with different distribution of diameters ranging from several hundred nanometers to approximately ten micrometers. Laser-textured surfaces were additionally hydrophobized using chemical vapor deposition of a few atomic layers thick fluorinated silane coating. The developed surface functionalization approach allows for rapid and simple fabrication of boiling surfaces capable of extreme boiling performance enhancement, which is also the topic of the ARRS research project Laser micro and nano structuring for development of biomimetic metallic surfaces with unique properties (LaMiNaS). Such surfaces open up the possibility of developing even more compact and powerful electronic systems.

The original scientific paper is available under CC BY license at: https://doi.org/10.1021/acsami.0c01594