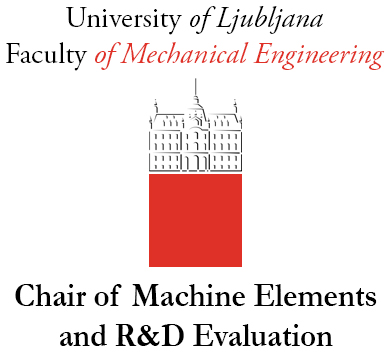

REBMIX algorithm for estimating finite mixture densities

- The primary purpose of the REBMIX algorithm is to estimate a finite mixture models. The mixed distribution functions can be the mixtures of normal, Weibull or lognormal distribution functions. The algorithm estimates the number of components, component weights and component parameters of the mixture distribution functions. The provided data set can be in the form of discrete values or in the form of histogram and it can belong to one or more random variables.

- The algorithm allows the generation of random points form known mixture distribution functions which can belong to normal, Weibull or lognormal distribution functions.

- The REBMIX algorithm with including source code that runs on all operating system's can be downloaded for free. Download REBMIX.

- The REBMIX algorithm works in R language.

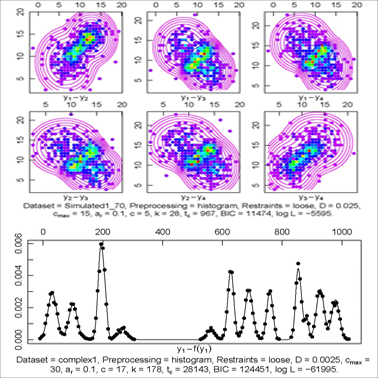

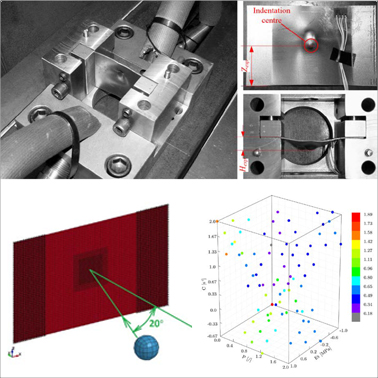

Simulation and evaluation of products made of hyper-elastic materials

- Finite element analysis of rubber composites.

- Fatigue life calculation of rubber components.

- Fatigue damage modelling of hyper-elastic material considering spatial stress-strain states.

- Design of dedicated testing machine for rubber components.

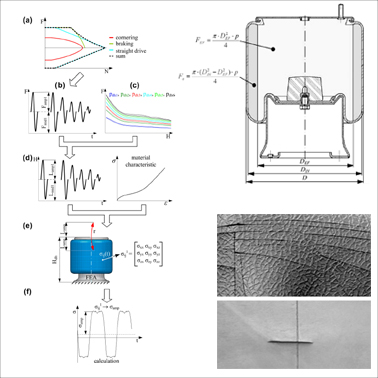

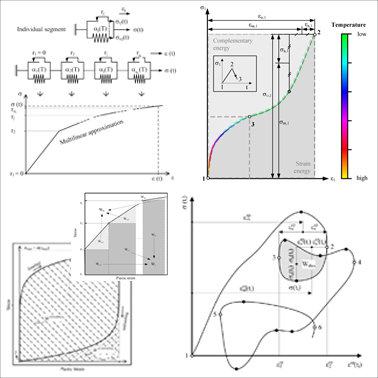

Thermo-mechanical fatigue

- Development of constitutive models for modeling the stress-strain states under thermo-mechanical loading.

- Development of constitutive models for the simulation of time-dependent phenomena such as cyclic creep and relaxation.

- Development of damage models to predict fatigue life taking into account multiaxial stress-strain states, temperature, strain rate, environmental effects and material properties.

- Design of experiments to determine the material parameters and fatigue life curves.

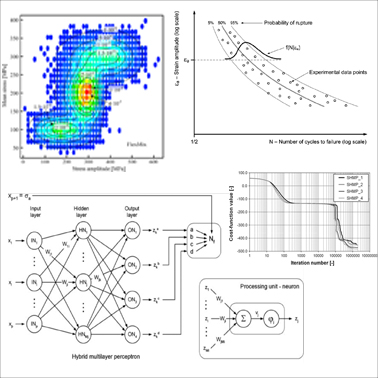

Characterization of material properties

- Design of experiments to determine the material parameters and fatigue life curves.

- Development of algorithms to estimate the scatter of experimental data set.

- Development of methods to optimize the number of tests to determine fatigue life curves.

- Modeling and predicting fatigue life of materials and structures by employing the methods of artificial intelligence and evolutionary algorithms.

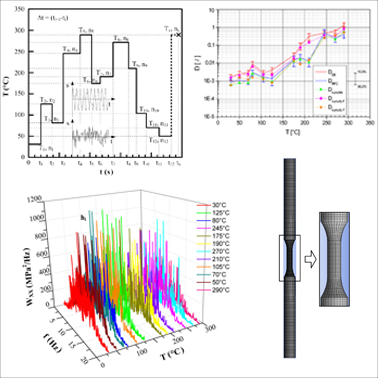

Impact of speed on material properties

- Design of experiments to determine the material parameters at high speed loading.

- Development of testing machines for determination of material properties at high speed loading.

- Determination of parameters of material models based on the experimental data by employing the methods of artificial intelligence and evolutionary algorithms.

Energy

- R&D of approaches for continuous energy calculation by taking into account particular material properties.

- Development of energy damage parameters with included mean stress correction.

- Development of energy models and calculation algorithms for fatigue damage modelling.

- Research of possible application of the developed energy approaches to other fields of study and materials.

Frquency based fatigue

- R&D of spectral methods for predicting fatigue damage in the frequency domain.

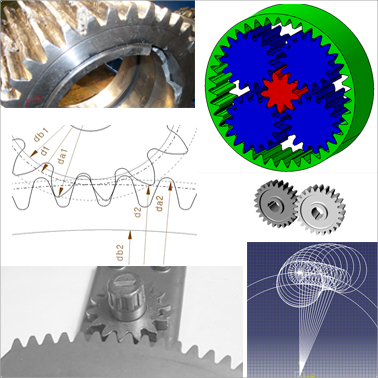

Gears

- Design of gear wheels made of metals and polymers according to DIN and EN-ISO standards.

- Geometric and kinematic analysis of gear wheels with non-standard thooting.

- Damage analysis of geers wheels and problem diagnostics.