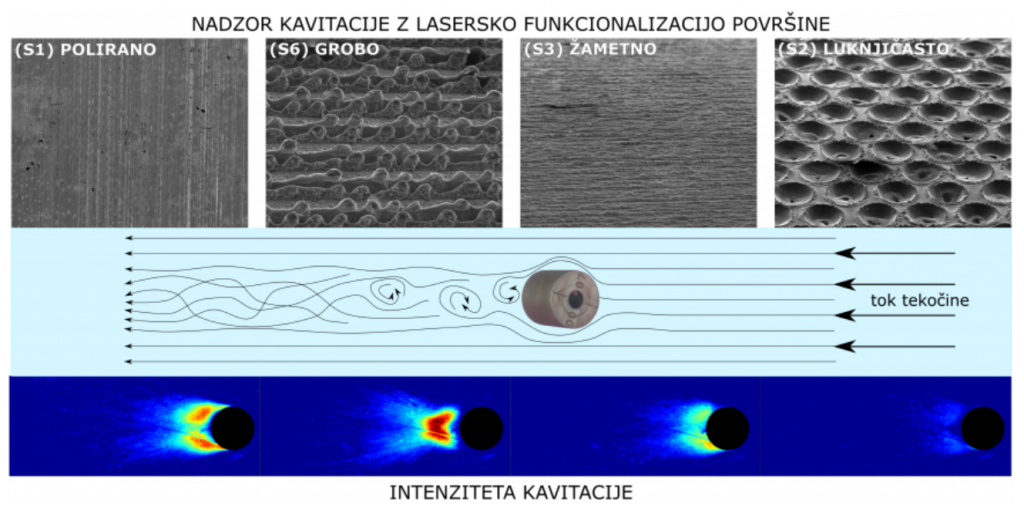

Laser surface functionalization for controlled hydrodynamic cavitation

4. May, 2020 23:10 | admin | News

In a paper, published in Ultrasonics Sonochemistry (IF = 7.279), Assist. Prof. Dr. Martin Petkovšek and Assist. Prof. Dr. Peter Gregorčič demonstrated that laser texturing can be used for modifications of three-dimensional surfaces enabling controlled hydrodynamic cavitation.

The interaction between liquid flow and solid boundary can result in cavitation formation when the local pressure drops below vaporization threshold. The cavitation dynamics does not depend only on basic geometry, but also on surface roughness, chemistry and wettability. From application point of view, controlling cavitation in fluid flows by surface functionalization is of great importance to avoid the unwanted effects of hydrodynamic cavitation (erosion, noise and vibrations). However, it could be also used for intensification of various physical and chemical processes.

In this work, the surfaces of 10-mm stainless steel cylinders are laser textured in order to demonstrate how hydrodynamic cavitation behavior can be controlled by surface modification. By using nanosecond-laser texturing, surfaces with five different topographies and different wettability were produced and tested in a cavitation tunnel. Cavitation characteristics behind functionalized cylindrical surfaces were monitored simultaneously by high-speed visualization (20,000 fps) and high frequency pressure transducers. The results clearly show that cavitation characteristics differ significantly between different micro-structured surfaces. On some surfaces, incipient cavitation is delayed and cavitation extent decreased in comparison with the reference – a highly polished cylinder.

The results prove that cavitation characteristics significantly depend not only on the surface roughness, but also on the surface wettability. The increased wettability (lower apparent contact angles) delays the incipient cavitation, since the liquid tends to stay in a contact with the hydrophilic surface. Thus, the liquid separates from the surface at higher flowrates (representing higher energies). Here, the development of the surface wettability on the laser- textured metallic surfaces by time offers an interesting approach to test the interaction between the fluid flow and the curved surfaces with the same micro-topography, but different wettability.

The presented results, that are also part of the ARRS research project Laser micro and nano structuring for development of biomimetic metallic surfaces with unique properties (LaMiNaS) clearly demonstrate that cavitation on the same basic geometry (cylinder) can be efficiently controlled by laser surface engineering. If appropriate laser-texturing parameters are used, cavitation can be decreased, or initial cavitation can be shifted to lower cavitation numbers. The visual observation and pressure measurements endorse the direct laser texturing as a potential technique for controlling cavitation dynamics. Thus, laser surface engineering is proven as a promising tool for modification of the surface properties leading to: (i) reduced risk of cavitation to appear or eventually reduced cavitation extent or its aggressiveness and, consequently, the cavitation erosion; and (ii) increased cavitation effects, when needed for, e.g., advanced oxidation processes.

The original scientific paper is available under CC BY 4.0 license at: https://doi.org/10.1016/j.ultsonch.2020.105126