PCA for industrial diagnostic of compressor connection rod defects

Neural Networks course (practical examples) © 2012 Primoz Potocnik

PROBLEM DESCRIPTION: Industrial production of compressors suffers from problems during the imprinting operation where a connection rod is connected with a compressor head. Irregular imprinting can cause damage or crack of the connection rod which results in damaged compressor. Such compressors should be eliminated from the production line but defects of this type are difficult to detect. The task is to detect crack and overload defects from the measurement of the imprinting force.

Contents

Photos of the broken connection rod

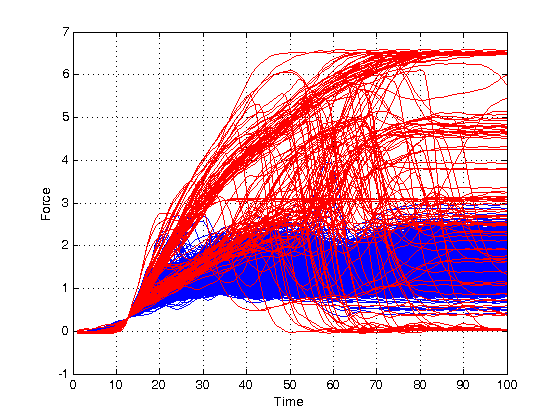

Load and plot data

close all, clear all, clc, format compact % industrial data load data2.mat whos % show data figure plot(force(find(target==1),:)','b') % OK (class 1) grid on, hold on plot(force(find(target>1),:)','r') % NOT OK (class 2 & 3) xlabel('Time') ylabel('Force')

Name Size Bytes Class Attributes force 2000x100 1600000 double notes 1x3 222 cell target 2000x1 16000 double

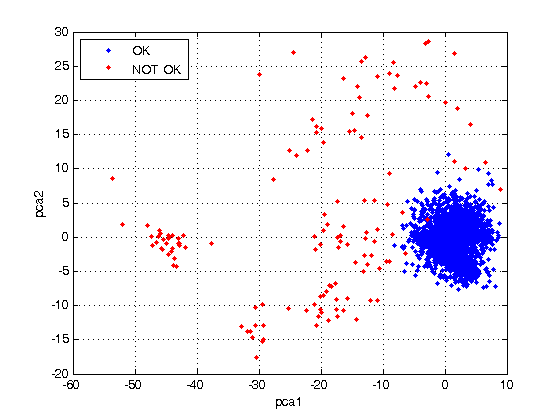

Prepare inputs by PCA

% 1. Standardize inputs to zero mean, variance one [pn,ps1] = mapstd(force'); % 2. Apply Principal Compoments Analysis % inputs whose contribution to total variation are less than maxfrac are removed FP.maxfrac = 0.1; % process inputs with principal component analysis [ptrans,ps2] = processpca(pn, FP); ps2 % transformed inputs force2 = ptrans'; whos force force2 % plot data in the space of first 2 PCA components figure plot(force2(:,1),force2(:,2),'.') % OK grid on, hold on plot(force2(find(target>1),1),force2(find(target>1),2),'r.') % NOT_OK xlabel('pca1') ylabel('pca2') legend('OK','NOT OK','location','nw') % % plot data in the space of first 3 PCA components % figure % plot3(force2(find(target==1),1),force2(find(target==1),2),force2(find(target==1),3),'b.') % grid on, hold on % plot3(force2(find(target>1),1),force2(find(target>1),2),force2(find(target>1),3),'r.')

ps2 =

name: 'processpca'

xrows: 100

maxfrac: 0.1000

yrows: 2

transform: [2x100 double]

no_change: 0

Name Size Bytes Class Attributes

force 2000x100 1600000 double

force2 2000x2 32000 double

Define output coding: 0=OK, 1=Error

% binary coding 0/1

target = double(target > 1);

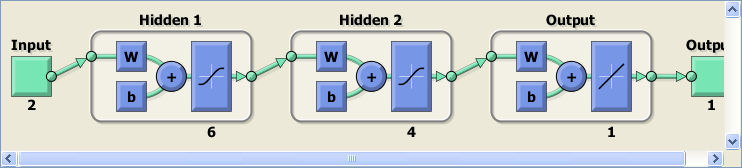

Create and train a multilayer perceptron

% create a neural network net = feedforwardnet([6 4]); % set early stopping parameters net.divideParam.trainRatio = 0.70; % training set [%] net.divideParam.valRatio = 0.15; % validation set [%] net.divideParam.testRatio = 0.15; % test set [%] % train a neural network [net,tr,Y,E] = train(net,force2',target'); % show net view(net)

Evaluate network performance

% digitize network response threshold = 0.5; Y = double(Y > threshold)'; % find percentage of correct classifications cc = 100*length(find(Y==target))/length(target); fprintf('Correct classifications: %.1f [%%]\n', cc)

Correct classifications: 99.6 [%]

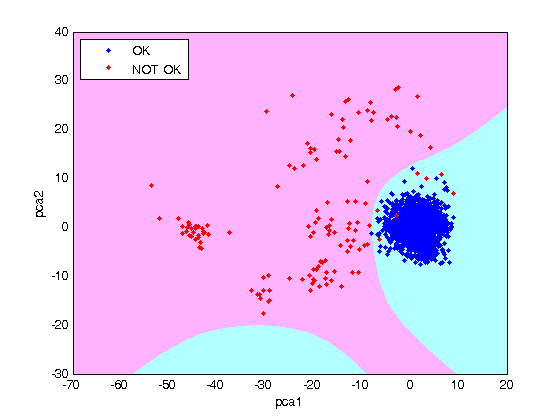

Plot classification result

figure(2) a = axis; % generate a grid, expand input space xspan = a(1)-10 : .1 : a(2)+10; yspan = a(3)-10 : .1 : a(4)+10; [P1,P2] = meshgrid(xspan,yspan); pp = [P1(:) P2(:)]'; % simualte neural network on a grid aa = sim(net,pp); aa = double(aa > threshold); % plot classification regions based on MAX activation ma = mesh(P1,P2,reshape(-aa,length(yspan),length(xspan))-4); mb = mesh(P1,P2,reshape( aa,length(yspan),length(xspan))-5); set(ma,'facecolor',[.7 1.0 1],'linestyle','none'); set(mb,'facecolor',[1 0.7 1],'linestyle','none'); view(2)