POLYMER PROCESSING – POLYLAB EXTRUDER

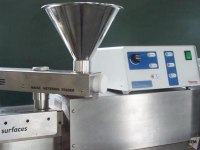

- Extruder Haake

- Metering feeder

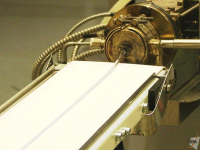

- Tape die

- Rod die

- Bath palletizer

- Die bath

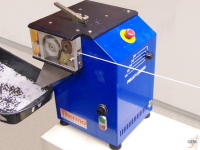

- Palletizer

- Products

Principle

Haake PolyLab OS PTW16/40 is extruder with two co-rotating 16 mm screws. Feeding is established with metering feeder or optional manual feeding through additional ports. Extruder barrel is divided into ten independent heating zones and one additional-die. For extrusion standard tape or rod die with different nozzles can be utilized or rod die with non-standard adapters for preparation of cylindrical samples.

Additional equipment allows fast cooling of extruded material in a water bath, slow cooling with using of conveyor belt and preparation of granules with a pelletizer. Haake software also allows monitoring of processing parameters (temperature, torque, pressure and screws speed) during extrusion.