CREEP CHARACTERIZATION

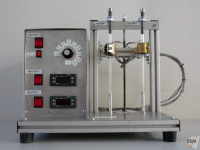

- Shear creep complete measuring system

- Shear creep torziometer

- POM specimen

- Aparatus for specimen preparation

Principle

Creep measurements are performed in order to characterize the deformation process of time-dependent solid materials when exposed to a constant loading stress (force). The Center for Experimental Mechanics at the Faculty of Mechanical Engineering, University of Ljubljana developed a measuring system[1],[2],[3] to conduct shear creep compliance measurements of solid materials at constant temperatures.

Procedure of creep measurements consists of:

- specimen preparation – gravimetrical casting into cylindrical shape, and gluing the sample to the metal holders adjusted to the grips of the apparatus;

- conditioning at elevated temperature with the next phase of slow cooling to the room temperature in order to erase thermo- mechanical history of the material;

- exchange of loading and unloading phases at different temperature levels following pre-determined temperature and mechanical loading profile;

- measurement of creep process at elevated temperatures, including temperature control, recording and storing of results.

Results

Following the pre-determined temperature and mechanical loading profile of the measurement, we obtain segments of torsional creep compliance for pre-determined temperature levels of the measuring procedure.

By using time-temperature superposition principle on the obtained creep compliance segments, master curve of the creep compliance as a function of time can be constructed for selected reference temperature.